Since the wide-scale implementation of quality systems in companies, the need for predictive-preventive maintenance has become one of the most significant demands in the market. Many companies that still have their own in-house technical maintenance team are deciding to subcontract these services from specialized companies, which are in turn quality certified and capable of accrediting said service within the specific systems set up by the quality departments of each company.

However, it is not simply a matter of complying with established regulations. There is also an interest in obtaining effective results that justify these investments. The diagnosis of electrical machinery is one specific term that sets a specialized repair center apart from the rest. Through this predictive maintenance, we are able to:

- Maintain control over the status of motors and monitor their evolution.

- Prevent malfunctions by detecting the anomalies that can cause them in time.

- Ensure that once inevitable repairs or interventions on the motors have been detected, they are less costly, since they have been identified in time.

- Ensure minimal machine down times, and thus potential unexpected interruptions in production.

- Avoid the scheduled replacement of serviceable bearings and unnecessary regular inspections of machines that are in good working order.

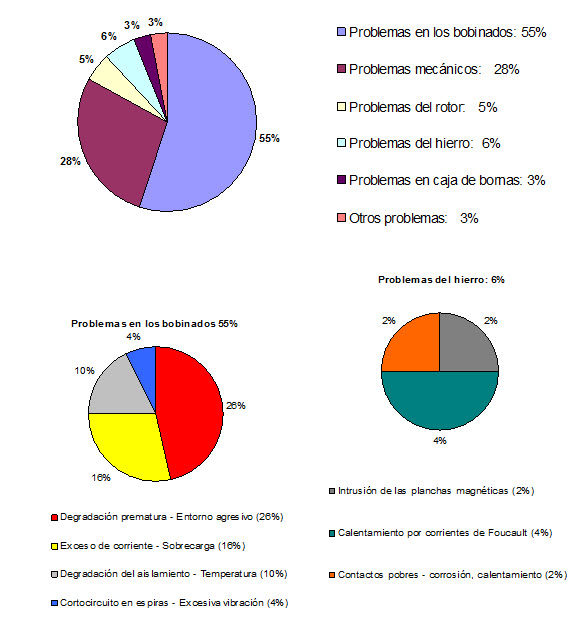

A rough study of the different types of malfunctions that can occur in electric motors reveals the failure rates:

| Problems with the windings: 55% | Premature deterioration – Aggressive environment (26%) |

| Excessive current – Overload (16%) | |

| Deterioration of the insulation – Temperature (10%) | |

| Short circuit in the coils – Excessive vibration (4%) | |

| Mechanical problems: 28% | Damaged bearings |

| Damaged axles: wear, torsion, cracks, etc. | |

| Miscellaneous: bench, keys, etc. | |

| Rotor problems: 5% | Broken cage bars |

| Broken short circuit rings | |

| Pores, cavities, etc. | |

| Problems with the iron: 6% | Intrusion of the magnetic plates (2%) |

| Heating by Foucault currents (4%) | |

| Problems with the terminal box: 3% | Poor contacts – corrosion, heating (2%) |

| Other problems: 3% | Cable friction – Vibration |

| Brushes, commutators. |

Studies show that even though only one fourth of the malfunctions correspond to motors above 40 kW, the cost of their repair represents nearly 80% of the total.

The monitoring of the insulation is especially important. As indicated above in the malfunction percentages, a progressive deterioration of the insulation causes a dangerous increase in temperature. The expected life of a motor, estimated to be around 24,000 hours or 10 years, is reduced by half when the motor is run continuously at 10 ºC above its maximum temperature of 120 ºC. If it is exceeded by 20 ºC, its life is reduced to one fourth of the estimated time, in other words, to two and a half years.

As part of the diagnoses carried out by MOTORLAN, in addition to static verification techniques performed when the motor is stopped, we pay special attention to checking the mechanical condition of the bearings, the overall condition of the motors (the effect of the structural looseness, imbalance as the result of machine vibrations, etc.).

The reports we provide after performing the diagnosis are structured as described below.

1.- Historic list of diagnosed motors: summary of the results obtained in previous diagnoses of each motor and expected future diagnoses. The first part consists of a list of diagnosed machines, along with their corresponding motors for quick location.

2.- Record for each motor, with the results of the data currently collected and the historical evolution of the different parameters analyzed. The analysis of each motor consists primarily of the following sections:

- Board data collection; to contrast later, while the machine is running. This lets us know how the motor is dimensioned and its current characteristics.

- Visual inspection; which in the case of a DC motor, is intended to analyze points such as the collector, brushes, brush quality, dimensions, etc.

- Insulation and winding resistance; these are two of the most important data that will provide the most information about the current condition of the motor and its evolution over time.

- Four-point vibration analysis; to verify whether the motor is within standards to prevent any possible deficiencies associated with the bearings and the coil heads.

- Bearing analysis; to determine its current operating mode in order to observe the later evolution based on a new data acquisition.

3.- Summary remarks on the data in the report; which provides details of the conclusions drawn for each motor, based on the results obtained and indicating the specific actions that are recommended to be taken.

Once all this data has been collected, the complete diagnosis report is sent. All the data collected are recorded on the computer system and are monitored based on newly acquired data and the related graphs to analyze their evolution. The diagnoses are generally performed every 6 months, although it always depends on each motor and its mode of operation.

We also have available:

- Portable spectral analysis equipment for certain cases in which important vibration problems can occur, which will enable us to know, among other things, their origin and any misalignments, in order to proceed in certain cases to perform the in situ balancing of the machine. For larger diameters, we have the capacity to balance rotors longer than 3 m (3,000 kg Æ =2 m). We also have portable equipment to check the windings, which even allows us to detect the deterioration of insulation between the coils through non-destructive tests.

- Thermography. Thanks to this technique, we foresee hot spots in motors and electrical installations that can cause serious malfunctions. Our thermographic inspections are carried out by our level II trained technicians, according to recommendation SNT-TC-1A.

The diagnosis service includes the drafting of the corresponding report and subsequent presentation in person, to comment on the incidents that have been observed.